While many talk about the challenges, Cody has solved them – with TITAAN

During the World Economic Forum in Davos in January 2015, German Chancellor Angela Merkel declared, among other things: "The time has come for a fusion between the internet world and industrial production. In Germany, we call it Industry 4.0 (I4). Later, Merkel clarified: The step towards digitalization of industrial production is a prerequisite for maintaining a high production rate – and standard of living."

TITAAN IS THE ANSWER

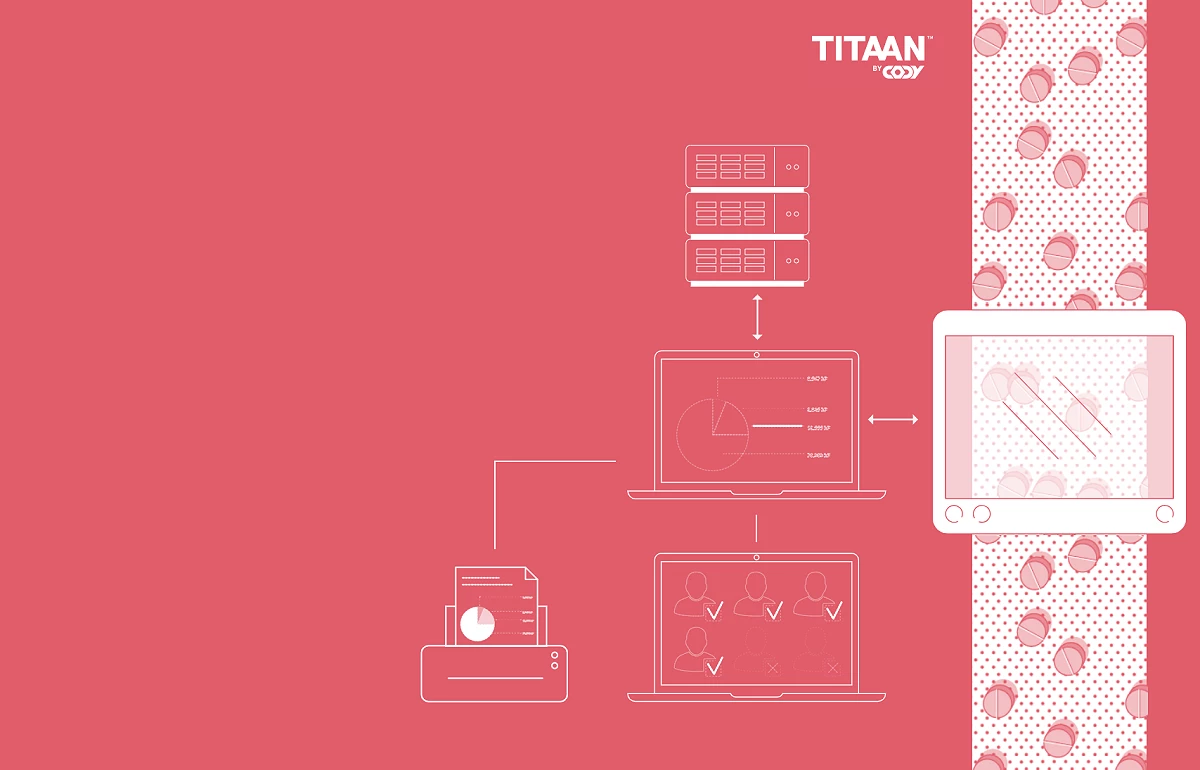

While there may be a number of definitions of I4, what they all have in common is a focus on an interface between all systems - machine and IT and from machine to machine. Cody has expertise on the OT/machine side – and on the database/PC/IT side. We have therefore created TITAAN as a “missing link” between the two worlds.

Despite the low entry cost and low user threshold: TITAAN answers Angela Merkel’s challenge. TITAAN is I4 in practice! In addition, TITAAN is the industry leader in price.

HOW IT WORKS

We see the complexity and we see that there are different platforms with different disciplines involved. We also see that some industries, such as pharmaceuticals, have high demands on data integrity, while others just want to get data from production to the IT side in the simplest possible way, in order to then run data analyses or machine learning tools. TITAAN solves all of this.

TITAAN suits both small and large businesses, is scalable, modular and expandable, and communicates up – and down – in two different platforms. More specifically, OPC towards the machine world – and SQL towards the IT world.

PROVEN QUALITY

Bayer produces the radioactive cancer drug Xofigo at the Institute of Energy Technology (IFE). In 2016, Cody was commissioned to develop and build an inspection and packaging line for this drug. With Bayer as one of the first customers, TITAAN was therefore developed according to pharmaceutical standards. It guarantees a level of functionality and security that is more than good enough for all industries.

Magnus is our Chief Business Development Officer, and with his experience in both mechanical design, automation, project management, and sales, he has full control over what Cody can deliver. He also delves deep into the Machinery Directive, CE marking, and harmonized standards to ensure that what we deliver complies with laws and regulations.