Bayer: Inspection and packing line

Bayer produces the radioactive cancer drug Xofigo at the Institute for Energy Technology in Norway (IFE). In 2016, Cody got the exciting assignment of developing and building an inspection and packing line for the medicine, based on past experience and collaboration with Bayer.

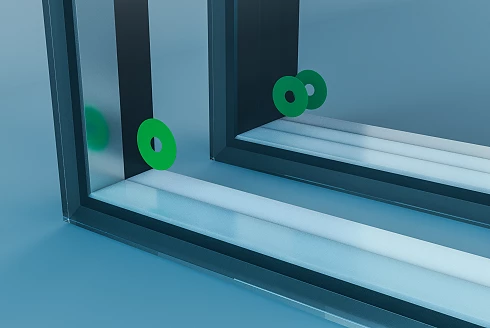

With a high focus on user-friendliness, operator safety and the demanding requirements that apply when building equipment for radiopharmaceutical production, Cody has created a solution that is tailored to IFE's production premises and needs. One of the challenges has been to create a machine with good operator accessibility while controlling the radiation hazard from the medicine at the same time.

In the development of the machine, the team need to meet the following criteria:

Small footprint

Measure radiation

Operator safety

Reducing radiation exposure

User friendliness

The machine design ensures that the user doses are automatically inspected and packaged, as the radiation hazard indicates that this cannot be done manually. The control system is complex and manages all vital production steps, including visual control of labels and packaging through advanced camera technology.

Cody's proprietary database solution TITAAN handles batch reporting, reconciliation, logging of critical production instrumentation, electronic signatures, and more. This is made according to the current pharmaceutical production directives.

Core functionality

Automated inspection and packaging

Ensures user doses are inspected and packaged without manual handling, eliminating unnecessary radiation exposure.Integrated vision system

Advanced technology verifies labels, packaging integrity, and product alignment in real time.Optical Character Verification (OCR)-based label verification

Automatically reads and validates printed data to prevent labeling errors and ensure full traceability.TITAAN production database

Cody’s proprietary system manages batch reporting, reconciliation, instrument logging, audit trails, and electronic signatures in line with pharmaceutical manufacturing requirements.GAMP 5–aligned system design

Developed following Good Automated Manufacturing Practice guidelines to support validated and auditable production environments.21 CFR Part 11 compliance

Supports secure electronic records and signatures for regulated pharmaceutical manufacturing.

Magnus is our Chief Business Development Officer, and with his experience in both mechanical design, automation, project management, and sales, he has full control over what Cody can deliver. He also delves deep into the Machinery Directive, CE marking, and harmonized standards to ensure that what we deliver complies with laws and regulations.