Solutions that bring you value

We work closely with our suppliers to stay updated. The systems we create ensure that our customers have oversight – all the way from sensors to control systems and reporting.

Production and process industries are becoming increasingly automated, often requiring complex systems to meet demands for productivity, reliability, and safety. At Cody, we understand the challenges the production industry faces in today's competitive market. That's why we focus on delivering customized automation solutions that streamline production processes and improve profitability.

We begin with an analysis of your current production processes to identify bottlenecks and areas for improvement. Based on the analysis, we develop tailored automation solutions best suited to the task. We ensure seamless integration of our solutions with your existing systems and minimize operational disruptions during implementation. We provide comprehensive training to your employees and offer support to ensure optimal use of automation technology.

We deliver complete stand-alone solutions, but we also have extensive experience integrating our solutions into existing production.

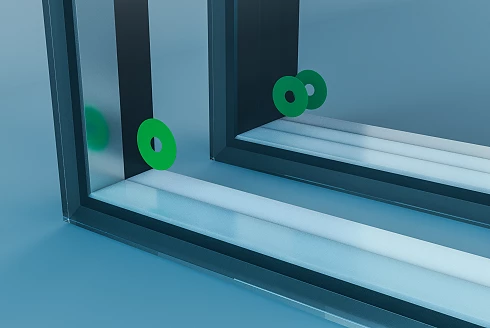

Camera Systems

Our vision solutions provide you with the ability to automate inspection and quality control with exceptional accuracy.

Quality Control: Automated inspection systems that quickly identify defects and deviations ensure that only the highest quality products reach the market.

Precision: Advanced cameras and imaging technology provide accurate measurement and verification of products and components.

Traceability: Our vision systems make it easy to track and document the production process, which is essential for quality management and certification.

Integration: Seamless integration with existing production lines and automation systems to ensure a smooth and efficient workflow.

Customization: Tailored solutions designed to meet specific needs and challenges in your production process.

Our vision systems offer a reliable and efficient way to monitor and improve the quality of your products, leading to increased customer satisfaction and strong financial performance.

Networking

We use reputable products, primarily from Allen Bradley, Phoenix Contact, and Cisco, to design a topology that ensures efficiency and security. We also offer solutions for remote connectivity and diagnostics on machines via our VPN structure.

Network Design: Robust and secure network infrastructure for your automation systems.

Remote Diagnostics: Monitor and diagnose systems remotely for quick problem resolution.

Logging, Recipe Management, and Reporting

Based on customer requirements, we offer products and services that enable traceability and analysis of production.

Data Collection: Automatic logging of critical production data.

Reporting: Customized reports that help you monitor performance and identify areas for improvement.

To simplify and ensure smooth data flow between customer IT systems and production machines (OT systems), we have developed software called TITAAN. TITAAN can capture production data in several ways. All data is timestamped and securely stored, making it available for automatic reporting, dashboard display, export, or search. Additionally, the software handles parameter changes and user actions (audit trail), electronic signatures, recipes, alarm logs, and reports. TITAAN is currently used by companies such as Bayer, ABB, and TechnipFMC.

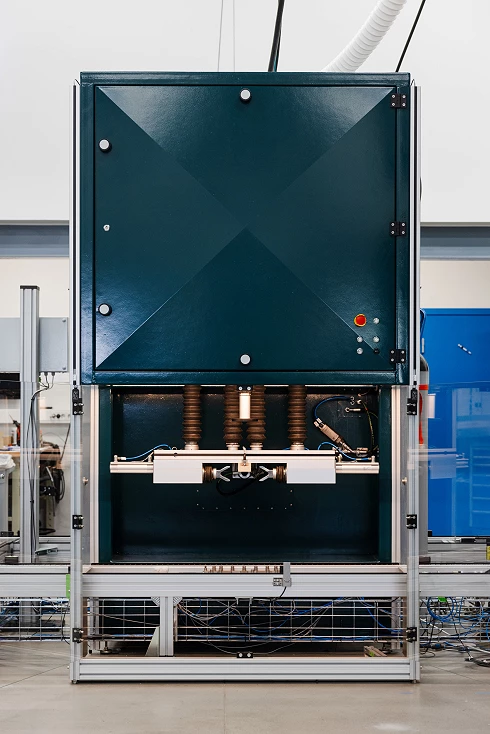

Servo Systems

Servo drive systems provide precise control over movement and position in automated processes. We have extensive experience with advanced servo systems from numerous projects.

Cody offers advanced servo drive solutions that enhance the performance and reliability of your machines and equipment.

Precise Control: High accuracy and responsive control for complex movements.

Efficiency: Reduces energy consumption and increases machine efficiency.

Flexibility: Many options in both size and design.

Instrumentation

Cody offers expertise in electronics and instrumentation to ensure that your systems operate with maximum efficiency and accuracy. Our machines are, of course, delivered with electrical schematics in accordance with applicable standards.

Precision: We use high-quality sensors and instruments for accurate measurement.

Integration: Our solutions can be seamlessly integrated with your existing systems.

Reliability: We ensure robust and reliable operation under all conditions.

Cody's engineers design, draft, and instrument the control system to create robust machines that meet customer requirements.