Miljø Norge: Automated recycling of fire extinguishers

Miljø Norge is an industrial company with a goal to reuse and increase the circularity of a number of products in the market. Their first circular product is fire extinguishers, where they want to help ensure that reuse replaces the need to import newly manufactured extinguishers. Outdated fire extinguishers are taken in for service and returned to the market, as good as new. We at Cody have collaborated with Environment Norway to create an efficient and flexible recycling process for these.

- We at Cody naturally support initiatives that save society from environmental footprints, and were involved here because there was great potential for automating the process of recycling fire extinguishers, says general manager at Cody, Ken André Myhra Kihle.

At the same time, there was a need for a lot of experimental development in the various parts of the process in order to be able to handle the large range of extinguishers and powder types. It has been demanding, but it gives an all the better feeling when you get it done!

Custom Solution with Gradual Automation

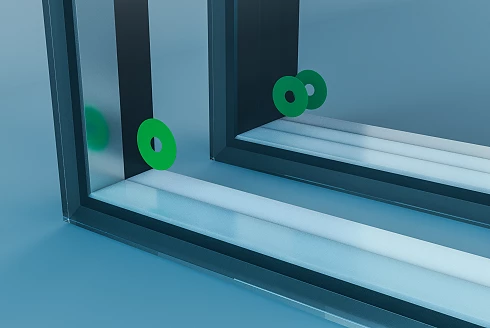

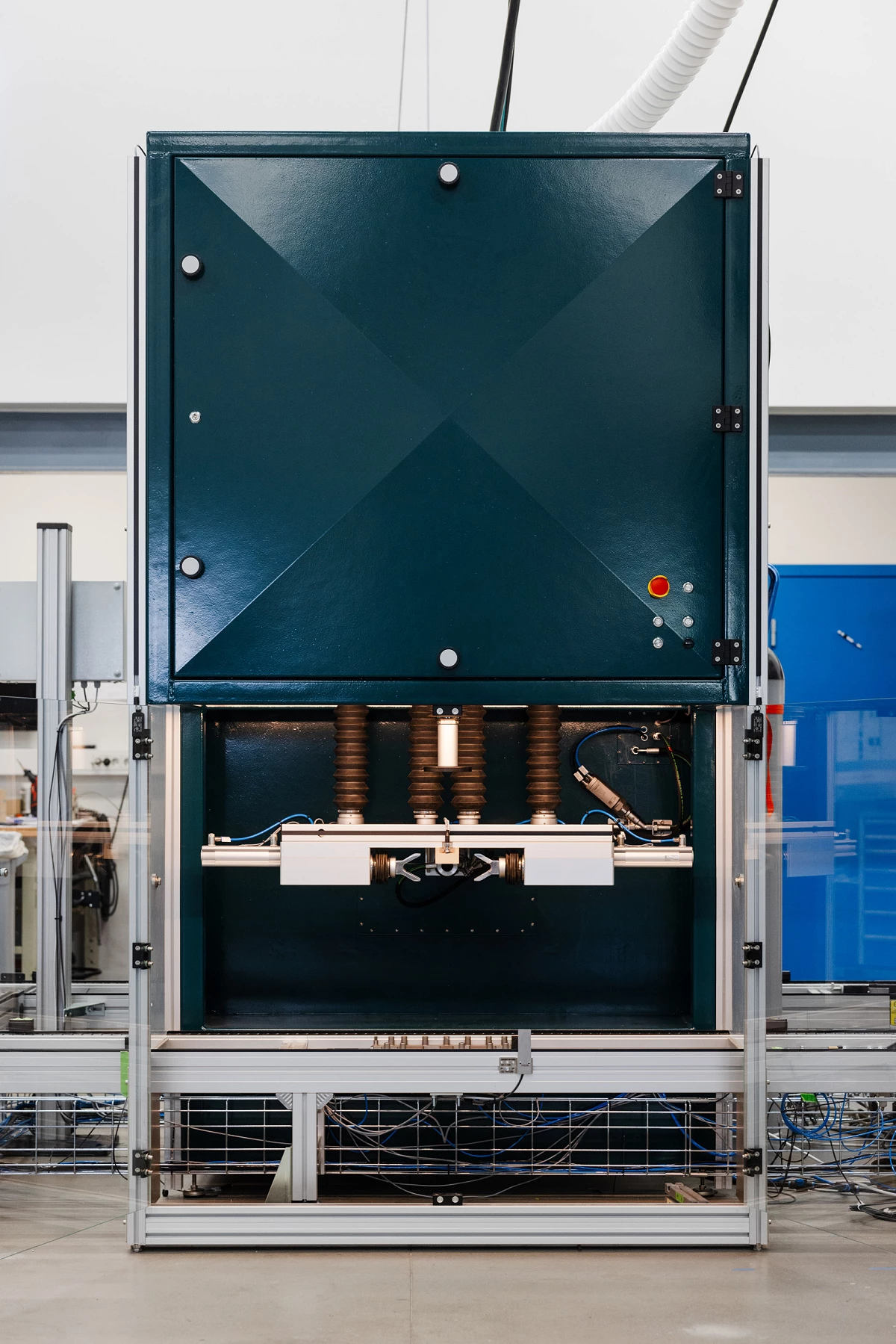

Cody has designed a complete production line with a modular approach, allowing each component to be further automated as needed. A pallet conveyor system has been set up where each pallet is tagged with an RFID, enabling tracking of the extinguishers throughout the process. Each station adjusts its operations according to the product and logs all production data using TITAAN.

We started with a mix of automated and manual stations. As the system is refined, manual operations are gradually replaced with automated ones. This approach is highly cost-effective because Miljø Norge can prioritize automation based on their needs. This allows for investment to be spread out rather than fully automating everything at once.

In 2022, we delivered the solution with 3 automated stations installed, and 3 more were added in 2023. These new stations have replaced more manual tasks, such as removing and unscrewing the handles on top.

“This has been an incredibly exciting project where we delivered a complete recycling solution while allowing Miljø Norge to incrementally increase the level of automation in line with their production needs. Both parties are satisfied with the solution, and we look forward to supporting Miljø Norge as they continue to evolve,” concludes Ken André.

Read more about this exciting solution on Miljø Norge’s own pages.

Ken André has a master’s degree in cybernetics from NTNU and has experience in programming, automation, control systems, and quality management. Since 2019, he has been our CEO.