TechTeach: Indoor climate rigs for use in education

Finn Aakre Haugen runs the company TechTeach and works part-time at the University of South-East Norway (Porsgrunn campus) and OsloMet, where he teaches control engineering. He conducts courses in control engineering for industry employees, apprentices, and vocational school students and has authored textbooks in the field.

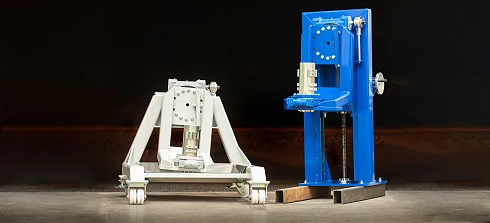

Several of us at Cody have been fortunate to have him as a lecturer during our education, and we have delivered two projects with mobile lab rigs that he uses in his courses.

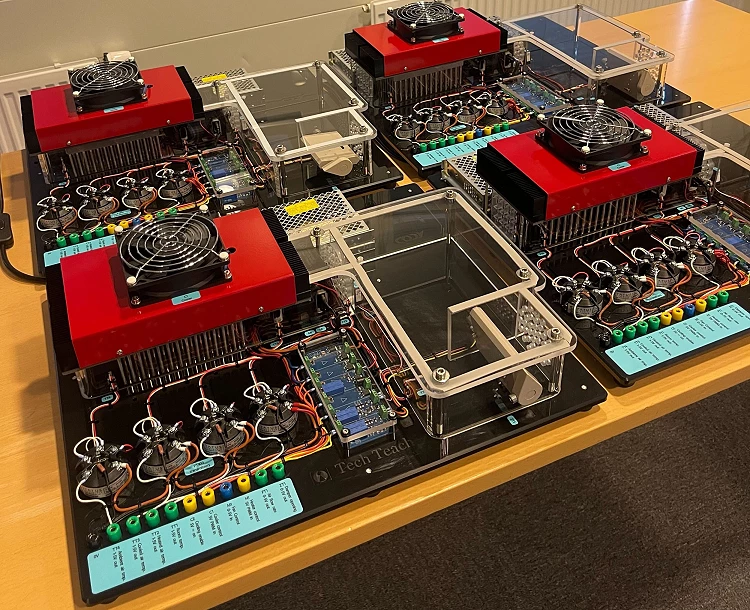

The latest project involves four indoor climate rigs. Previously, we completed a similar project involving a motor rig for speed control.

“Makes difficult things understandable”

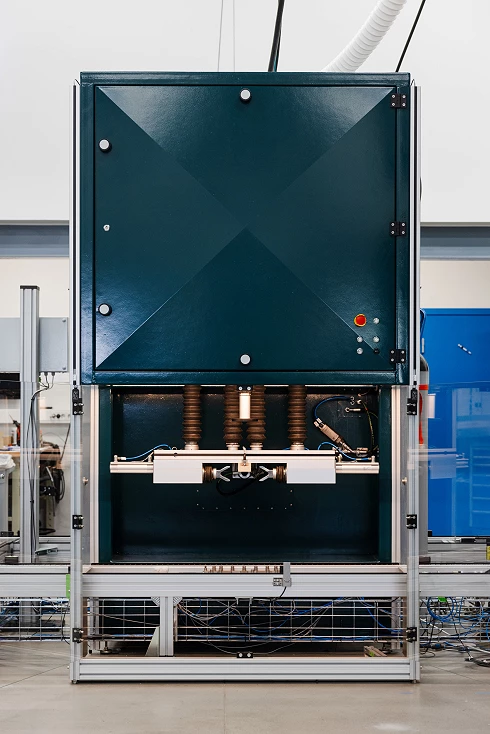

The indoor climate rig, where temperature and airflow are regulated, is very well suited for teaching fundamental methods in practical control engineering. The principles, mathematics, and mindset can be applied to many other control engineering applications.

Finn from the client TechTeach states that these indoor climate rigs will be used for experimentation. Students are given tasks such as maintaining a constant indoor temperature in a small room on the rig at a setpoint of 25 degrees Celsius or cooling it down to 18 degrees Celsius, ensuring it remains steady at the setpoint. The airflow through the room should also be regulated to the setpoint to provide sufficient air quality through adequate supply of fresh air to the room.

“"I am very pleased with the collaboration with Cody. They have been a great discussion partner during the development phase and have followed up on requests for adjustments along the way. The project was delivered on time and with top quality."” – Finn Aakre Haugen, TechTeach.

One of the challenges in the project was finding available components of good quality within the right price range and compact enough to be used in the limited space we had available. There was a requirement that all I/O should be in the form of voltage signals within 0-5 V to provide flexibility in the choice of I/O equipment. It was necessary to create a custom circuit board to integrate everything properly. We designed the board in-house and conducted simulations of the analog circuits before sending the design for production.

Automation engineer at Cody, Einar Ottestad, says this about the project: "It's very exciting to be able to take something that surrounds us in most daily activities, namely control engineering, and make it into something 'real' that people can understand. An important aspect is that the users of the rig should have an overview of the various components contributing to the process, i.e., actuators and sensors, so the rigs are designed in a way that maximizes visibility of as many components as possible, allowing users to follow the connections between them."

"The climate rigs can be connected to a PC running, for example, pre-developed LabVIEW apps to control the rigs. There, one can read meters, draw diagrams, and control the temperature, among other functions. Alternatively, industrial automation equipment such as PLCs and process controllers can be connected to the rig. Together with the specially designed circuit board for signal adaptation, this provides excellent opportunities for an educational experience," concludes Einar.

Ken André has a master’s degree in cybernetics from NTNU and has experience in programming, automation, control systems, and quality management. Since 2019, he has been our CEO.