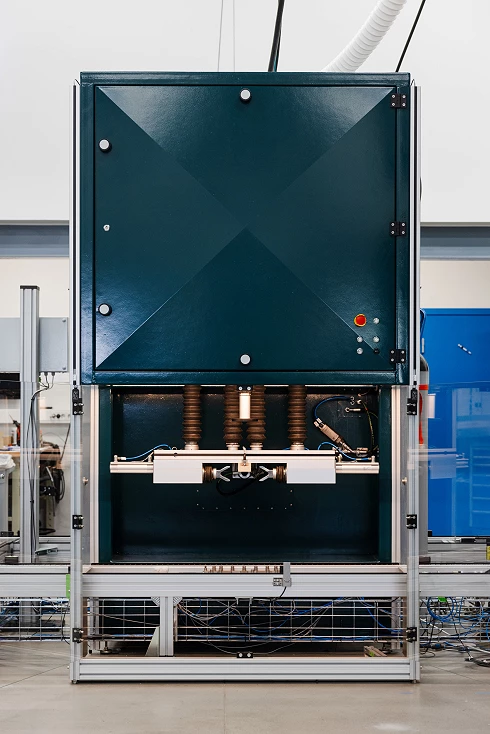

TechnipFMC: Needle bearing assembly tool

Cody has developed a number of production tools for Technip FMC Kongsberg. TechnipFMC produces high-tech products where safety, accuracy and control of production are absolutely essential to meet their customers' requirements and expectations. In this context, we have created a tool for pressing in needle bearings into machined components - with automatic logging of results from the process.

The tool itself is designed from the ground up, based on TechnipFMC's specific functional requirements, and has a control system based on Cody's digital solution TITAAN. The system guides the operator through the work process and provides feedback on whether the operations are successful or rejected. When a product is fully assembled, an electronic report is generated that contains all the results, the product's serial number, and the ID of the operator who performed the assembly. The report can be sent to a higher-level ERP or MES system.

The assembly of bearings is a critical step in production, and with a tool like this, it is possible to monitor and detect any errors that may occur during the process, allowing them to be corrected before they become costly and affect later production.

This machine demonstrates how TITAAN can be used to ensure quality and documentation in manual and semi-automatic operations in a production environment.

Magnus is our Chief Business Development Officer, and with his experience in both mechanical design, automation, project management, and sales, he has full control over what Cody can deliver. He also delves deep into the Machinery Directive, CE marking, and harmonized standards to ensure that what we deliver complies with laws and regulations.