GreenBox – A pioneering project for the process industry in the green transition

The project, led by battery manufacturer Vianode, has secured an impressive 75 million NOK in government funding through the Green Platform scheme. Cody is proud to be part of this exciting initiative.

Norway's ambitions are clear: we aim to have the world's cleanest, most modern, and energy-efficient process industry. This will be achieved through high-tech solutions and significant value creation. The roadmap for the process industry sets a goal of a 30% reduction in CO2 emissions by 2030, with a final vision of net zero or lower by 2050. Digitalization, new technology, and the use of artificial intelligence will be crucial in reaching these ambitious targets.

GreenBox aims to be at the forefront of developing the green, digital factory that will form the basis for upgrades and new establishments in Norway's process industry for decades to come. The goal is clear: to develop green competitive advantage. This means maintaining competitiveness while achieving sustainable environmental outcomes. This includes the development and implementation of sustainable solutions, reducing the climate footprint, efficient resource utilization, and employing innovative technologies to meet future environmental requirements and create a sustainable competitive edge in the market.

The supplier industry is central to achieving these goals.

The project involves several companies with various roles. Vianode’s planned factory at Herøya will serve as a testbed for new technology, while Elkem, Hydro, the Future Materials Catapult Center, and the Eyde Cluster will help spread innovation throughout the process industry. Cody, Cybernetica, Tratec Norcon, and Tunable are participating as technology suppliers with the aim of developing new products and solutions that can be widely scaled within the process industry. NORCE and SINTEF will ensure that the latest research is applied to selected focus areas.

To succeed in the digitalization of Norway's process industry, it is crucial to establish alliances and collaborations between supplier companies and the process industry. Suppliers, including Cody, play a central role in disseminating technology across the process industry and other sectors.

Vianode has been selected to test instrumentation and digital models in parallel with the design and construction of the new factory at Herøya. The technology will first be tested in an existing industrial pilot (2024), then in the Herøya factory (2025-2026), and finally be ready for full-scale implementation when the factory starts up in 2027. The goal is an efficient production process with minimal downtime, high yield, and maximum safety from day one.

Cody's Role in the Project

As a project partner and part of further value creation beyond the project, we will gain rights to the developed products and equipment that can become part of our product portfolio and be used for commercialization in the process industry.

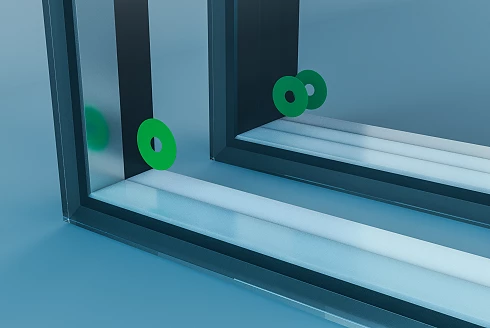

“Our specific task is to develop automated, efficient solutions for sample analysis processes, which are currently very time-consuming and manual. Often, the right person is required for a good sample result, and many results need to be discarded. We have great respect for the industry and how the processes are currently set up, but we hope to improve the testing process to make it faster and easier with accurate results every time. This is not something that happens overnight, but we are very eager to be part of this development,” says Jared Hansen, Project Manager at Cody.

“For us at Cody, it’s incredibly exciting to be part of this project. We want to work more closely with the process industry than we have before and be involved in driving innovation and creativity in this sector. It is a priority for us as a company to be involved from an early stage, engage in research, and be proactive in finding new solutions, rather than just using established knowledge and experience. This ensures we challenge ourselves and stay at the forefront of what we excel in,” says Ken Andre Myhra Kihle, CEO of Cody.

“A crucial aspect of GreenBox is obtaining detailed, rapid, and reliable data about our processes and materials. We conduct a wide range of material characterizations at various stages of synthetic graphite production, but most of these processes are currently manual. Cody's work in the project to develop automated solutions for graphite sample preparation will be vital in enhancing the measurement of our materials, leading to even more sustainable anode materials.” – Gunstein Skomedal, project manager Vianode.

A milestone for green innovation: 573 million NOK awarded

The Green Platform is an initiative that provides funding to businesses and research institutions for research and innovation-driven green transition efforts. This initiative is a collaboration between the Research Council of Norway, Siva, and Innovation Norway. Its goal is to foster a socio-economically profitable and sustainable business sector that contributes to the green transition.

Recently, the Green Platform scheme awarded a total of 573 million NOK to nine projects, including GreenBox. These significant research and innovation projects aim to develop climate and environmentally friendly solutions within industry. Among the exciting projects are initiatives for charging infrastructure for heavy transport, recycling of old ships, and converting plastic packaging into food products.

You can read more about all the projects receiving support here.

Ken André has a master’s degree in cybernetics from NTNU and has experience in programming, automation, control systems, and quality management. Since 2019, he has been our CEO.