ABB: Assistance for production solutions and products for 20 years

External specialist expertise adds value to both products and production at Skien's largest workplace, ABB. For 20 years, Cody's problem solvers have assisted in the production and development of ABB's advanced switchgear, which ensures power delivery around the world.

- Cody has extensive experience and expertise that we benefit from. We often bring in Cody's specialized crew to optimize production, says Yrjan Bergsmark, Engineer at ABB Skien.

- We challenge Cody with both ideas and problems, and in close collaboration we develop solutions for ABB's three factories in Skien.

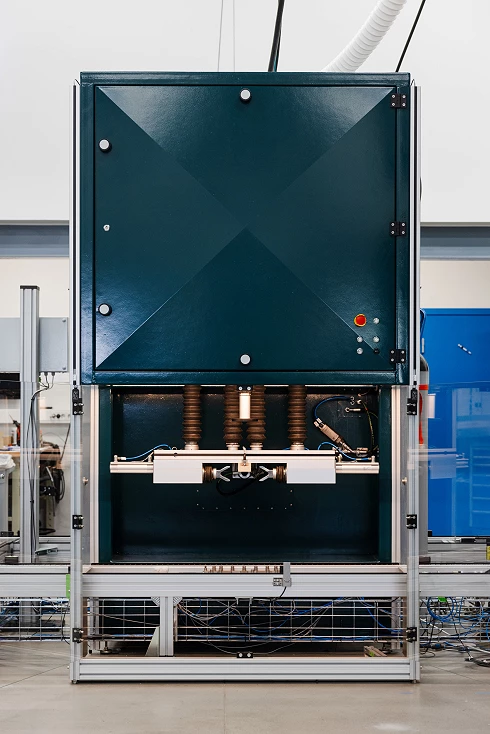

Every year, ABB sends a significant number of medium-voltage installations, substations and switchboards to Norway and the rest of the world. It provides a stable power supply that protects people, equipment and buildings. In the three high-tech factories in Skien, very strict requirements are placed on production equipment and test systems.

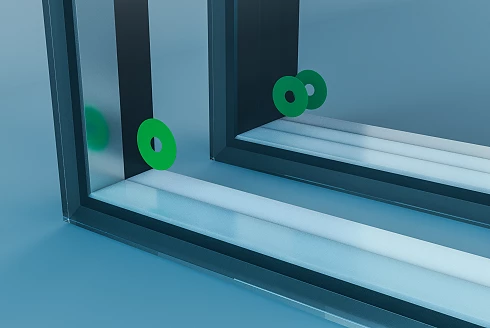

- Among other things, Cody has led the project to upgrade four automatic test stations with a new control system and data storage. The tests to be carried out must follow an international standard and form the basis of a certificate, therefore data quality is crucial, explains Bergsmark about one of the many collaborations between ABB and Cody.

The production lines at the factories in Skien are largely manual, but the focus on automation, data capture and storage is increasing. Improvements to bottlenecks, efficient assembly jigs, implementation of new equipment, recording and analysis of production data are some of the tasks that Cody delivers to ABB. - We are very satisfied with Cody's database solution called Titaan, where we benefit from Cody's experience with deliveries to the pharmaceutical industry.

ABB's products from Skien ensure traditional power supply for households, business and small industry, but also have special facilities for new power producers in wind and solar energy. The latest smart systems have computers that allow monitoring and remote control.

- We are problem solvers for challenges, says Ken André Myhra Kihle, General Manager of Cody. - ABB has been a customer of ours since the start and we know the systems and products very well. There must be a short path from problem to solution, with optimal response time. We move out regardless of the time of day.

Yrjan Bergsmark can confirm that Cody put the 2020 summer holidays on hold when ABB received an urgent challenge in July.

- Cody has a large network and can obtain both technical parts and expertise that we do not have access to ourselves. There is a high ceiling for discussing the most innovative ideas and we meet in creative and solution-oriented processes, which help us safeguard ABB Skien's role in our international organisation, concludes Bergsmark.

ABOUT ABB IN SKIEN

ABB Electrification Norway AS offers a broad portfolio of products, digital solutions and services, from transformer stations to sockets, which enable safe, smart and sustainable electrification. The offer includes digital and connected innovations for low and medium voltage, including electric car/electric bus infrastructure, modular substations, distribution automation, protection, cables and cabling equipment, electrical panels, cabinets, instrumentation and control.

ABB in Skien is the municipality's largest private workplace and has around 750 employees. The company develops, manufactures, supplies and exports electrotechnical equipment to over 80 countries for the generation and distribution of electricity.

Ken André has a master’s degree in cybernetics from NTNU and has experience in programming, automation, control systems, and quality management. Since 2019, he has been our CEO.