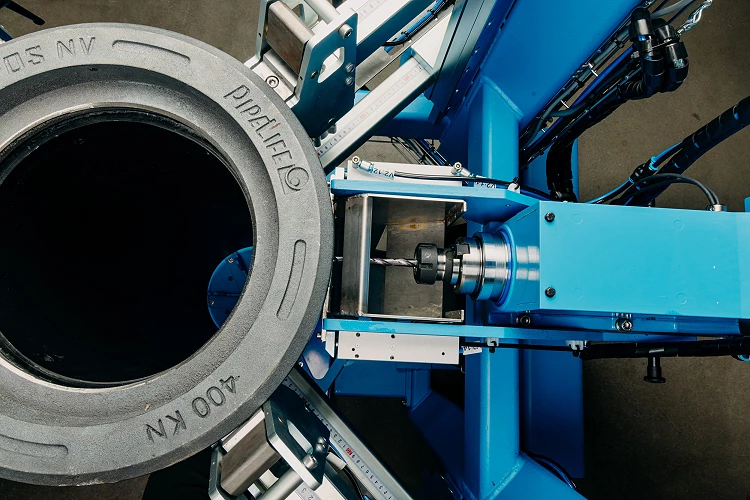

Custom Drilling Machine for Leading Manhole Cover Manufacturer

Precision Drilling for Heavy Industry

Precision Drilling for Heavy Industry

Smart Automation for Smarter Casting

We developed a robust drilling unit tailored to Ulefos’ high-demand foundry environment—boosting speed, safety, and consistency.

Tailored Technology for Norwegian Industry

Cody’s solution helps Ulefos streamline manhole production with a compact, automated drilling unit designed for daily industrial use.

Engineered for Harsh Environments

This drilling machine is built to perform in the tough conditions of a cast iron foundry—delivering power, control, and repeatability.

Making Foundry Work Flow Smoother

When Ulefos needed a better way to drill manholes, we built a machine that works as hard as they do—day in, day out.

We have completed our first major project for Ulefos Jernværk. Ulefos reached out to us when they needed an improved process for the production of manhole rings.

Cody partnered with Ulefos, one of Europe’s most established producers of cast iron manhole covers and infrastructure products, to design and deliver a fully automated drilling machine tailored to their unique production needs. This collaboration showcases how specialized machinery can enhance precision, speed, and safety in heavy industry.

The process has existed for a long time, and is both manual and cumbersome, and not HSE-friendly. We took up the challenge and ensured that they now have a machine that does the same job, but in a more efficient way, in addition to guaranteeing that it will be a perfect result every time. This relieves the operators, is simpler, faster, safer and cheaper.

We delivered the machine in April this year, and what was delivered was a completely different product to the one originally ordered. - With good communication along the way, we constantly came up with new changes and adaptations that resulted in a more universal machine than originally intended, says project manager at Cody, Anders Laursen.

“"We are satisfied with the product we have been delivered, simply the result of good cooperation."” – Torgrim Andersen, site manager, Ulefos Jernværk

Magnus is our Chief Business Development Officer, and with his experience in both mechanical design, automation, project management, and sales, he has full control over what Cody can deliver. He also delves deep into the Machinery Directive, CE marking, and harmonized standards to ensure that what we deliver complies with laws and regulations.