FabLab´s - The future of tailor-made FMCG

Fra innsikt til innovasjon. Klar for fremtiden.

I tett samarbeid med SINTEF har Cody utviklet en kompakt, fremtidsrettet maskin designet for å støtte personlig produksjon. Med fokus på fleksibilitet og skalerbarhet markerer den starten på en ny æra for skreddersydd produksjon innen FMCG.

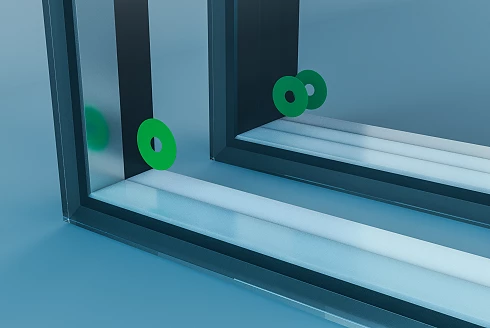

Fleksible formatendringer. Ingen verktøy nødvendig.

Cody har utviklet et system som tilpasser seg flere emballasjeformater – helt uten behov for verktøy. Rask og automatisk omstilling gir brukerne mulighet til å utvikle og tilpasse egne produkter uten å redusere produksjonshastigheten.

Skreddersydd av Cody

For Cody utløste utfordringen ny, dristig ingeniørtenkning og tett, tverrfaglig samarbeid.

Fra prototype til skalerbar produksjon

Systemet er et bevis på at prototyping og industriell ytelse ikke lenger trenger å være to separate verdener – det er en plattform for vekst.

Drevet av nysgjerrighet.

Se hvordan Cody kan ta ideen din fra prototype til produksjon.

As partners in an EU-funded project that began in 2019, Cody has developed two so-called FabLabs (fabrication laboratories). The project aims to give consumers the ability to customize their own consumer goods, such as shampoo, makeup, dietary supplements, and food.

As partners in an EU-funded project that started in 2019, Cody has developed two so-called FabLabs (fabrication laboratories). The project's goal is to enable consumers to customize their own consumer goods, such as shampoo, makeup, dietary supplements, and food. The project involves six companies and seven research institutions, representing seven different EU countries, with SINTEF serving as the project coordinator.

SINTEF was already familiar with Cody through previous collaborations and therefore reached out to see if we were interested in participating in this project.

TWO MACHINES HAVE BEEN DELIVERED AND INSTALLED

In December 2022, it was confirmed that the installation of the two FabLabs was successful. One is located at the large industrial incubator CPI in Durham, UK, and the other at SINTEF in Porsgrunn, Norway. Both organizations aim to test the machines in the coming months to explore their potential and how they can be used for various purposes and in different industries.

A CHANGE IN CONSUMER BEHAVIOUR

A major trend within consumer goods is a desire and need for these to be more adaptable to the individual consumer's preferences. Consumers are becoming increasingly aware of their own needs. They are concerned about what suits their lifestyle, and many think about their environmental footprint. Producing consumer goods on a smaller scale, which are both more personalized and more sustainable, is a challenge in an industry that is largely based on large-scale production and "one size fits all". This is where FabLabs comes into play. Precisely to try to meet consumer demand for tailored consumer goods, and a more sustainable production.

GREAT POTENTIAL

The FabLab that has now been delivered to CPI's state-of-the-art research facility is specially designed to produce liquid FMCG, while the one at SINTEF is designed for powder-based FMCG. The starting point is that the machines today support the production of specially adapted detergents, but what they are used for can easily be changed by changing modules.

The project will also identify industries that have particular market potential for specially adapted consumer goods. By demonstrating the safe and efficient operation of this machine, the conditions are created so that the small-scale production of thousands of customized products, from cosmetics, vitamins and dietary supplements to household products, snack bars and drinks is no longer a distant dream!

Learn more about the FabLabs In the video below:

Ken André has a master’s degree in cybernetics from NTNU and has experience in programming, automation, control systems, and quality management. Since 2019, he has been our CEO.