Newsletter

Receive the latest news from Cody by e-mail

Pharmacy

Pharmacy

NORWAY'S LEADING SUPPLIER OF SPECIALLY DESIGNED SOLUTIONS FOR PHARMACEUTICAL PRODUCTION

Cody supplies specially designed solutions for several different industries, and over the past ten years has increasingly invested in our experience in production equipment for pharmaceuticals. Delivering specially designed equipment to this industry is demanding, and you must have full control over material selection, design, functionality and the machine's digital control system. Cody has built up solid expertise in this through several years of collaboration with pharmaceutical companies such as Bayer, GE Healthcare and Vistin Pharma. GMP is at the forefront of Cody's employees' minds, and we deliver the systems fully validated and ready for production. We see that our customers particularly appreciate that we understand the industry terminology and can deliver solutions they are confident in. Pharmacy and radiopharmacy place particularly high demands on traceability, batch accounting and access control, for which we have created our own solutions.

VALIDATED DATA CAPTURE

In the work with the development of production machines in the pharmaceutical industry, Cody has seen the need for a digital solution to collect and store data from new and existing machines and make these available for various IT platforms. In short: "The missing link" between the production machines and the company's overall IT system. That is why we have created our own software called TITAAN which covers this need and which meets the industrial requirements for pharmaceutical production (GAMP5, 21 CFR Part 11). TITANIUMcan capture data from production in several different ways. All data is time-stamped and stored securely and available for automatic reporting, display in a dashboard, export or search. In addition, the program handles parameter changes and user actions (audit trail), electronic signatures, prescriptions, alarm logs and reports. TITAAN is currently used by Bayer , ABB and TechnipFMC , among others .

MODULAR PRODUCTION AND CUSTOMIZED PRODUCTS

Due to our experience in machine design, in 2019 we received a request from Sintef to become a partner in a European research project that aims to develop and test a complete value chain for "personalized fast-moving consumer goods". The aim is to facilitate the competitive production of tailor-made products, i.e. small batches, as well as the validation of prescriptions. The EU's investment in "Factories of the Future" enabled this project to receive support via the Horizon 2020 programme.

The best comparison to say something about what this project is about is the machines that mix the right color for you at the paint store. Initially, we will develop mini-factories that can produce detergents, but in the long term the aim is that mini-factories can produce personally adapted products in everything from baked goods to pharmaceuticals. We see great potential for this within the pharmaceutical industry, although the strict regulatory requirements naturally present additional challenges here.

The mini-factory, where the products are made, will be assembled from different production modules that add different properties to the product. Some modules may have heating as their task, while others may have to shake or stir the ingredients in a certain way. The entire mini-factory is built up so that modules can be added to the rest of the production facility without the existing components needing to be changed. Basically, this machine, with small changes, should be able to produce almost anything. If we want to make bread with it, we might make a kneading module, a rising module and a baking module, and thus we have created a baking machine.

BROAD EXPERIENCE

Since its inception, Cody has invested in special machines within a wide range of industries. We see that our varied competence and experience is the key to finding the optimal solutions in new projects, whether it is in the field of advanced assembly equipment for subsea products, aids or medical equipment. Alongside our main business in the development of production machinery and related equipment, Cody also undertakes assignments in product development. Here, too, the breadth is large with products such as green loose ammunition, sensor systems and the aforementioned aids. We have a constant eye on cost-effective production, and are constantly thinking that it should be possible to produce the products we develop in a good way. We can follow a project from the idea of a product, through the development process and all the way to automated production.

01

SALES MANAGER

Magnus Skoglund Larsen

Magnus is our sales manager and with experience in mechanical design, automation and project management. He has deep knowledge in laws, directives and standards and performs risk analysis and compliance testing.

+47 991 22 505 magnus@cody.noProjects

-

BAYER INSPECTION AND PACKING LINE

Complete inspection and packaging line for a radioactive cancer drug, which is produced by Bayer at the Institute of Energy Technology (IFE)

Learn more ⟶ -

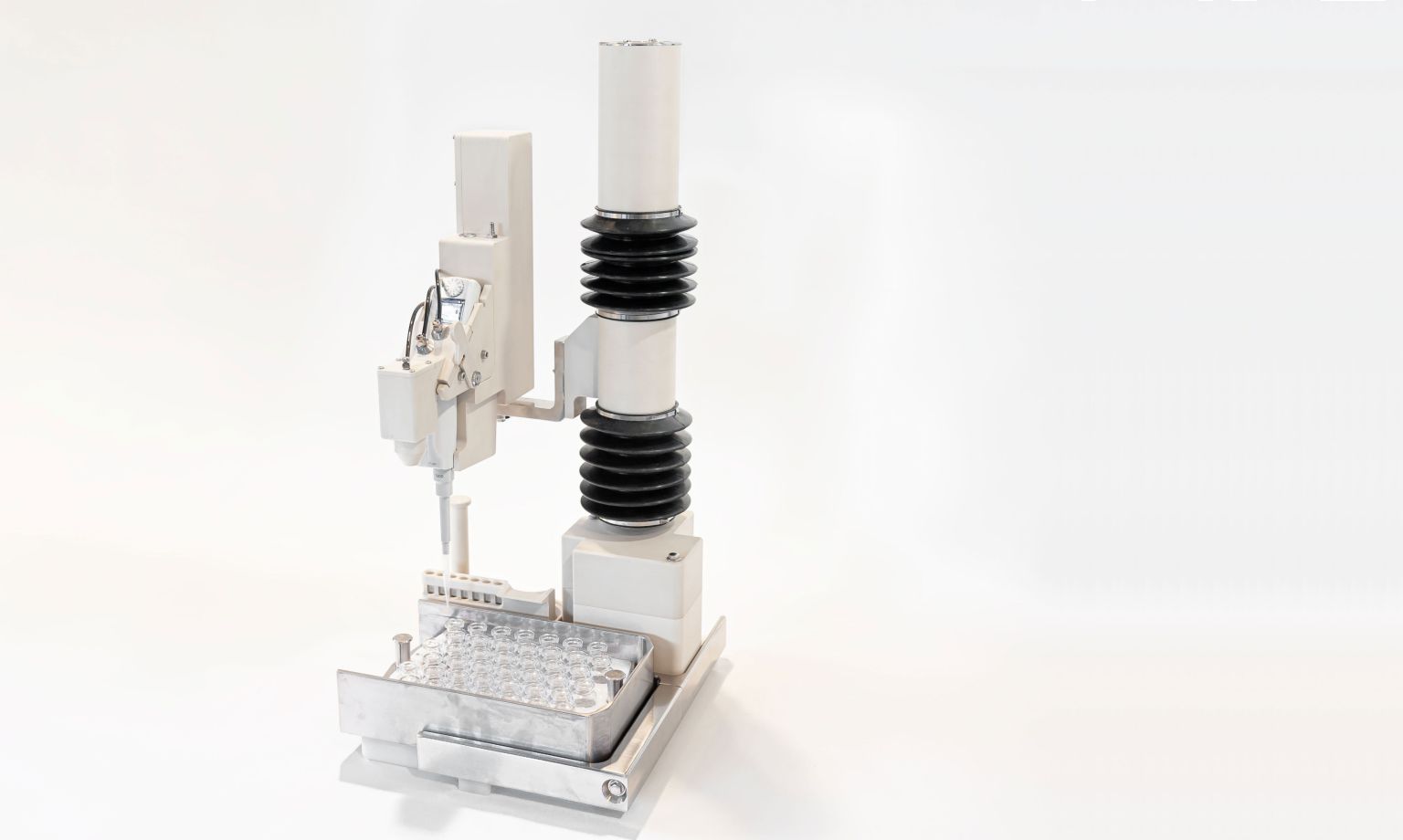

Thorium-robot

Cody has had the pleasure of delivering a very special robot for dispensing the radionuclide thorium-227

Learn more ⟶ -

Titaan - a "Missing link" between IT and OT

The road to Industry 4.0 requires an interface between all systems; between machine and IT and from machine to machine.

Learn more ⟶