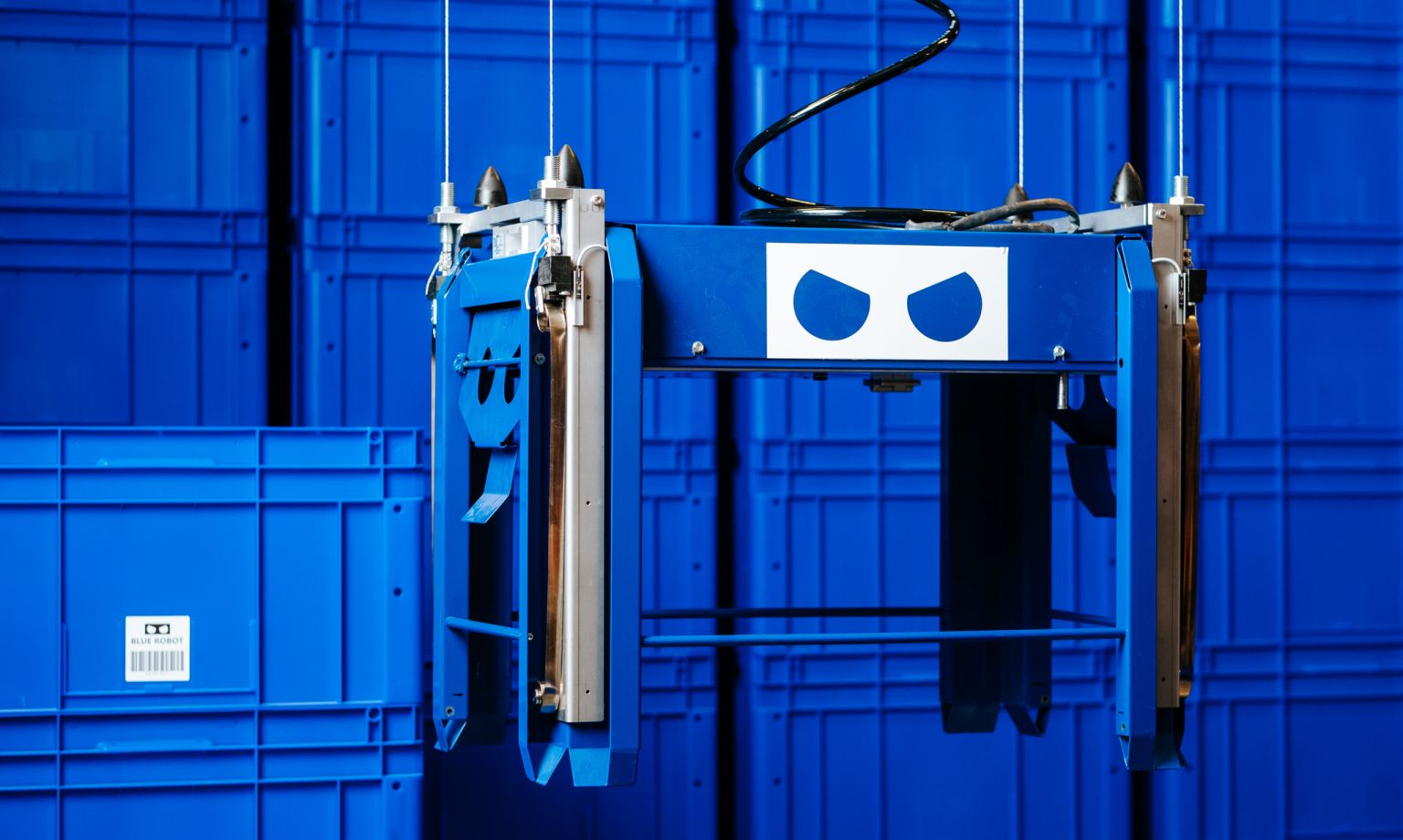

Norwegian Blue Robot AS has developed advanced technology for efficient automation of goods flow. The solution only requires a stable surface, a ceiling height of four metres, electricity and internet. This opens the way for smaller players in the merchandise trade to easily adopt warehouse automation.

- Our goal was to develop robotic picking technology that is easy to install, has high operational reliability and, not least, is effective for a customer group that has not previously had access to warehouse automation, says Arnor Jonasson, General Manager of Blue Robot AS.

In collaboration with Cody, Blue Robot had time and cost as the leading parameters for the development of a robust technology, which is based on advanced artificial intelligence.

- The solution has standardized components, of the highest quality. It provides very stable operation. Furthermore, we have always focused on the systems being compatible with the customer's existing software and hardware, for efficient installation and a minimum of investment costs, explains Jonasson.

EASY INSTALLATION FACILIATES FOR A QUICK IMPLEMENTATION

The warehouse cube is easily installed in the customer's premises, and only requires a stable surface, a ceiling height of four meters and internet access. Artificial intelligence with advanced algorithms streamlines the placement of goods and boxes, and optimizes the handling of orders and dispatches.

- We have broad experience from retail, and therefore a clear need for simpler solutions for warehouse automation. Very few players in the market are so large that they can defend investments in inventory management that exceed turnover, says the General Manager.